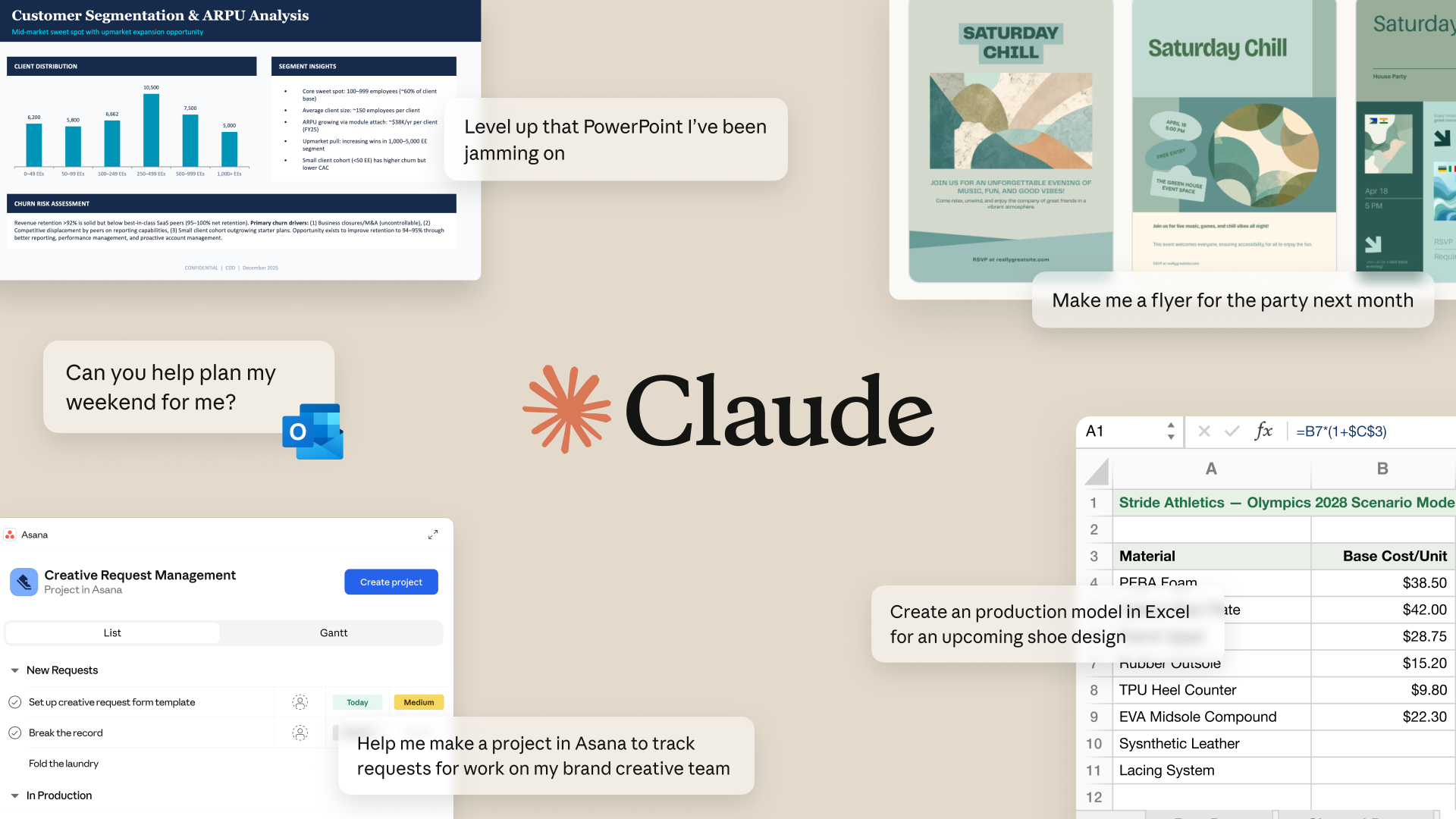

Leading peelable heat shrink tubing specialist, Junkosha, has announced the launch of its Clear Peelable Heat Shrink Tubing product, a ‘next-level’ solution enabling catheter manufacturers to achieve exceptional clarity, reduced assembly risk, and streamlined processes.

Alongside its growing Peelable Heat Shrink Tubing range, Junkosha says that its ‘significant expansion’ in both capacity and manufacturing capabilities has provided customers with increased options in both its Peelable Heat Shrink Tubing and Etched PTFE Liner ranges.

Speaking to Med-Tech Insights, Caroline Herdman, Global Product Specialist at Junkosha said: “The benefits of our clear, peelable and heat shrink tubing is that we can offer it in 2.0:1 shrink ratio, all the way down to 1.2:1 shrink ratio. It’s really useful for the engineer that just wants to do a benchtop trial. So if they want to do a quick, fast, easy trial, see what’s happening with the catheter build, you’ve got the transparency to see what’s happening.

“Also, if you’ve got something that you want to see on the shop floor, when it’s in production, if there’s a need to see like a marker band for example, then we also have our clear offering for those needs. So, whether a customer wants translucent or transparent, we can do both.

Between 2021 and 2025, Junkosha reports that it has increased production capacity by 300% across its medical device affiliated product portfolio. This includes a doubling of capacity for its Peelable Heat Shrink Tubing and Liner ranges thanks to investments in new machines and resources. In a sector where both innovation and reliable availability are critical, Junkosha is ensuring that its pioneering solutions are accessible to customers as they continue to push the boundaries of new interventional products and therapies that improve patient outcomes.

“Over the last few years, we have significantly expanded our capacity, all while keeping open communication at the core of how we work with customers to fulfil their unmet needs,” explains Mike Winterling, Chief Operating Officer for Junkosha USA. “This approach means we are able to build stronger partnerships and ensure expectations are set through our process.”

“As minimally invasive procedures are increasingly more sophisticated, catheter features like multi-durometer shafts, braided or coiled reinforcements and laser-cut structures are becoming standard,” said Herdman. “At the same time this added functionality is driving the complexity of devices ever higher. Device manufacturers are utilising multiple pebax durometers to increase flexibility where it is needed, but also maintain the mechanical performance necessary for a smooth delivery. Junkosha is committed to advancing assembly solutions that meet these evolving needs, leveraging Clear Peelable Heat Shrink Tubing and future innovations to support OEMs and engineering teams.”