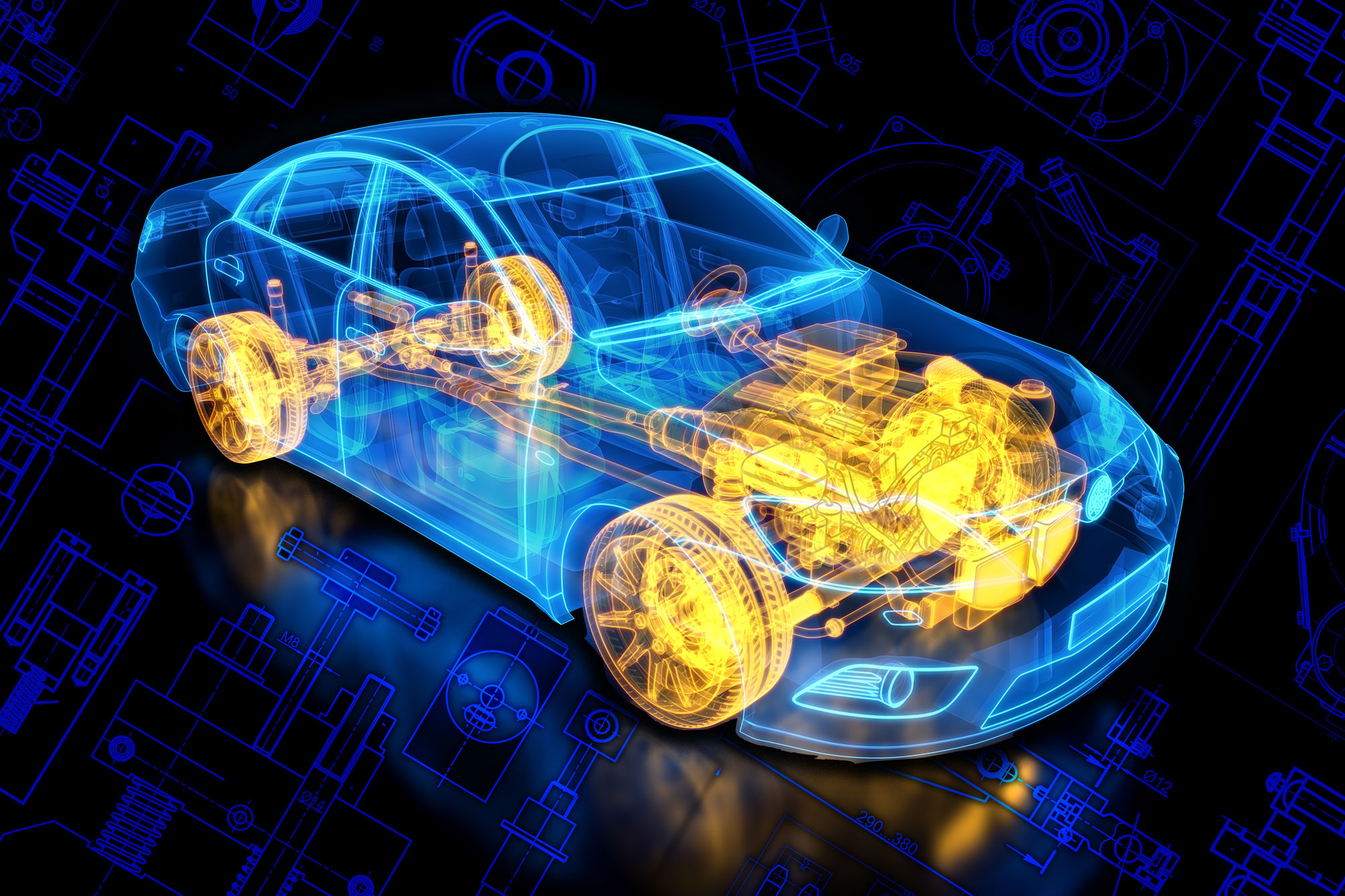

at a major automotive manufacturer, watching engineers celebrate what they thought was a breakthrough. They’d used generative AI to optimize a suspension component: 40% weight reduction while maintaining structural integrity, completed in hours instead of the usual months. The room buzzed with excitement about efficiency gains and cost savings.

But something bothered me. We were using technology that could reimagine transportation from scratch, and instead, we were making slightly better versions of parts we’ve been manufacturing since the 1950s. It felt like using a supercomputer to balance your checkbook: technically impressive, but missing the point entirely.

After spending three years helping automotive companies deploy AI solutions, I’ve noticed this pattern everywhere. The industry is making a fundamental mistake: treating generative AI as an optimization tool when it’s actually a reimagination engine. And this misunderstanding might cost traditional automakers their future.

Why This Matters Now

The automotive industry stands at an inflection point. Electric vehicles have removed the central constraint that shaped car design for a century—the internal combustion engine. Yet most manufacturers are still designing EVs as if they need to accommodate a big metal block under the hood. They’re using AI to make these outdated designs marginally better, while a handful of companies are using the same technology to ask whether cars should look like cars at all.

This isn’t just about technology; it’s about survival. The companies that figure this out will dominate the next era of transportation. Those that don’t will join Kodak and Nokia in the museum of disrupted industries.

The Optimization Trap: How We Got Here

What Optimization Looks Like in Practice

In my consulting work, I see the same deployment pattern at almost every automotive manufacturer. A team identifies a component that’s expensive or heavy. They feed existing designs into a generative AI system with clear constraints: reduce weight by X%, maintain strength requirements, stay within current manufacturing tolerances. The AI delivers, everyone celebrates the ROI, and the project gets marked as a success.

Here’s actual code from a traditional optimization approach I’ve seen implemented:

from scipy.optimize import minimize

import numpy as np

def optimize_component(design_params):

"""

Traditional approach: optimize within assumed constraints

Problem: We're accepting existing design paradigms

"""

thickness, width, height, material_density = design_params

# Minimize weight

weight = thickness * width * height * material_density

# Constraints based on current manufacturing

constraints = [

{'type': 'ineq', 'fun': lambda x: x[0] * x[1] * 1000 - 50000},

{'type': 'ineq', 'fun': lambda x: x[0] - 0.002}

]

# Bounds from existing production capabilities

bounds = [(0.002, 0.01), (0.1, 0.5), (0.1, 0.5), (2700, 7800)]

result = minimize(

lambda x: x[0] * x[1] * x[2] * x[3], # weight function

[0.005, 0.3, 0.3, 7800],

method='SLSQP',

bounds=bounds,

constraints=constraints

)

return result # Yields 10-20% improvement

# Example usage

initial_design = [0.005, 0.3, 0.3, 7800] # thickness, width, height, density

optimized = optimize_component(initial_design)

print(f"Weight reduction: {(1 - optimized.fun / (0.005*0.3*0.3*7800)) * 100:.1f}%")This approach works. It delivers measurable improvements — typically 10-20% weight reduction, 15% cost savings, that sort of thing. CFOs love it because the ROI is clear and immediate. But look at what we’re doing: we’re optimizing within constraints that assume the current design paradigm is correct.

The Hidden Assumptions

Every optimization embeds assumptions. When you optimize a battery enclosure, you’re assuming batteries should be enclosed in separate housings. When you optimize a dashboard, you’re assuming vehicles need dashboards. When you optimize a suspension component, you’re assuming the suspension architecture itself is correct.

General Motors announced last year they’re using generative AI to redesign vehicle components, projecting 50% reduction in development time. Ford is doing similar work. So is Volkswagen. These are real improvements that will save millions of dollars. I’m not dismissing that value.

But here’s what keeps me up at night: while traditional manufacturers are optimizing their existing architectures, Chinese EV manufacturers like BYD, which surpassed Tesla in global EV sales in 2023, are using the same technology to question whether those architectures should exist at all.

Why Smart People Fall into This Trap

The optimization trap isn’t about lack of intelligence or vision. It’s about organizational incentives. When you’re a public company with quarterly earnings calls, you need to show results. Optimization delivers measurable, predictable improvements. Reimagination is messy, expensive, and might not work.

I’ve sat in meetings where engineers presented AI-generated designs that could reduce manufacturing costs by 30%, only to have them rejected because they’d require retooling production lines. The CFO does the math: $500 million to retool for a 30% cost reduction that takes five years to pay back, versus $5 million for optimization that delivers 15% savings immediately. The optimization wins every time.

This is rational decision-making within existing constraints. It’s also how you get disrupted.

What Reimagination Actually Looks Like

The Technical Difference

Let me show you what I mean by reimagination. Here’s a generative design approach that explores the full possibility space instead of optimizing within constraints:

import torch

import torch.nn as nn

import numpy as np

class GenerativeDesignVAE(nn.Module):

"""

Reimagination approach: explore entire design space

Key difference: No assumed constraints on form

"""

def __init__(self, latent_dim=128, design_resolution=32):

super().__init__()

self.design_dim = design_resolution ** 3 # 3D voxel space

# Encoder learns to represent ANY valid design

self.encoder = nn.Sequential(

nn.Linear(self.design_dim, 512),

nn.ReLU(),

nn.Linear(512, latent_dim * 2)

)

# Decoder generates novel configurations

self.decoder = nn.Sequential(

nn.Linear(latent_dim, 512),

nn.ReLU(),

nn.Linear(512, self.design_dim),

nn.Sigmoid()

)

def reparameterize(self, mu, logvar):

"""VAE reparameterization trick"""

std = torch.exp(0.5 * logvar)

eps = torch.randn_like(std)

return mu + eps * std

def forward(self, x):

"""Encode and decode design"""

h = self.encoder(x)

mu, logvar = h.chunk(2, dim=-1)

z = self.reparameterize(mu, logvar)

return self.decoder(z), mu, logvar

def generate_novel_designs(self, num_samples=1000):

"""Sample latent space to explore possibilities"""

with torch.no_grad():

z = torch.randn(num_samples, 128)

designs = self.decoder(z)

return designs.reshape(num_samples, 32, 32, 32)

def calculate_structural_integrity(design):

"""

Simplified finite element analysis approximation

In production, this would interface with ANSYS or similar FEA software

"""

# Convert voxel design to stress distribution

design_np = design.cpu().numpy()

# Simulate load points (simplified)

load_points = np.array([[16, 16, 0], [16, 16, 31]]) # top and bottom

# Calculate material distribution efficiency

material_volume = design_np.sum()

# Approximate structural score based on material placement

# Higher score = better load distribution

stress_score = 0

for point in load_points:

x, y, z = point

# Check material density in load-bearing regions

local_density = design_np[max(0,x-2):x+3,

max(0,y-2):y+3,

max(0,z-2):z+3].mean()

stress_score += local_density

# Normalize by volume (reward efficient material use)

if material_volume > 0:

return stress_score / (material_volume / design_np.size)

return 0

def calculate_drag_coefficient(design):

"""

Simplified CFD approximation

Real implementation would use OpenFOAM or similar CFD tools

"""

design_np = design.cpu().numpy()

# Calculate frontal area (simplified as YZ plane projection)

frontal_area = design_np[:, :, 0].sum()

# Calculate shape smoothness (gradient-based)

# Smoother shapes = lower drag

gradients = np.gradient(design_np.astype(float))

smoothness = 1.0 / (1.0 + np.mean([np.abs(g).mean() for g in gradients]))

# Approximate drag coefficient (lower is better)

# Real Cd ranges from ~0.2 (very aerodynamic) to 0.4+ (boxy)

base_drag = 0.35

drag_coefficient = base_drag * (1.0 - smoothness * 0.3)

return drag_coefficient

def assess_production_feasibility(design):

"""

Evaluate how easily this design can be manufactured

Considers factors like overhangs, internal voids, support requirements

"""

design_np = design.cpu().numpy()

# Check for overhangs (harder to manufacture)

overhangs = 0

for z in range(1, design_np.shape[2]):

# Material present at level z but not at z-1

overhang_mask = (design_np[:, :, z] > 0.5) & (design_np[:, :, z-1] < 0.5)

overhangs += overhang_mask.sum()

# Check for internal voids (harder to manufacture)

# Simplified: count isolated empty spaces surrounded by material

internal_voids = 0

for x in range(1, design_np.shape[0]-1):

for y in range(1, design_np.shape[1]-1):

for z in range(1, design_np.shape[2]-1):

if design_np[x,y,z] < 0.5: # empty voxel

# Check if surrounded by material

neighbors = design_np[x-1:x+2, y-1:y+2, z-1:z+2]

if neighbors.mean() > 0.6: # mostly surrounded

internal_voids += 1

# Score from 0 to 1 (higher = easier to manufacture)

total_voxels = design_np.size

feasibility = 1.0 - (overhangs + internal_voids) / total_voxels

return max(0, feasibility)

def calculate_multi_objective_reward(physics_scores):

"""

Pareto optimization across multiple objectives

Balance weight, strength, aerodynamics, and manufacturability

"""

weights = {

'weight': 0.25, # 25% - minimize material

'strength': 0.35, # 35% - maximize structural integrity

'aero': 0.25, # 25% - minimize drag

'manufacturability': 0.15 # 15% - ease of production

}

# Normalize each score to 0-1 range

normalized_scores = {}

for key in physics_scores[0].keys():

values = [score[key] for score in physics_scores]

min_val, max_val = min(values), max(values)

if max_val > min_val:

normalized_scores[key] = [

(v - min_val) / (max_val - min_val) for v in values

]

else:

normalized_scores[key] = [0.5] * len(values)

# Calculate weighted reward for each design

rewards = []

for i in range(len(physics_scores)):

reward = sum(

weights[key] * normalized_scores[key][i]

for key in weights.keys()

)

rewards.append(reward)

return torch.tensor(rewards)

def evaluate_physics(design, objectives=['weight', 'strength', 'aero']):

"""

Evaluate against multiple objectives simultaneously

This is where AI finds non-obvious solutions

"""

scores = {}

scores['weight'] = -design.sum().item() # Minimize volume (negative for minimization)

scores['strength'] = calculate_structural_integrity(design)

scores['aero'] = -calculate_drag_coefficient(design) # Minimize drag (negative)

scores['manufacturability'] = assess_production_feasibility(design)

return scores

# Training loop - this is where reimagination happens

def train_generative_designer(num_iterations=10000, batch_size=32):

"""

Train the model to explore design space and find novel solutions

"""

model = GenerativeDesignVAE()

optimizer = torch.optim.Adam(model.parameters(), lr=0.001)

best_designs = []

best_scores = []

for iteration in range(num_iterations):

# Generate batch of novel designs

designs = model.generate_novel_designs(batch_size=batch_size)

# Evaluate each design against physics constraints

physics_scores = [evaluate_physics(d) for d in designs]

# Calculate multi-objective reward

rewards = calculate_multi_objective_reward(physics_scores)

# Loss is negative reward (we want to maximize reward)

loss = -rewards.mean()

# Backpropagate and update

optimizer.zero_grad()

loss.backward()

optimizer.step()

# Track best designs

best_idx = rewards.argmax()

if len(best_scores) == 0 or rewards[best_idx] > max(best_scores):

best_designs.append(designs[best_idx].detach())

best_scores.append(rewards[best_idx].item())

if iteration % 1000 == 0:

print(f"Iteration {iteration}: Best reward = {max(best_scores):.4f}")

return model, best_designs, best_scores

# Example usage

if __name__ == "__main__":

print("Training generative design model...")

model, best_designs, scores = train_generative_designer(

num_iterations=5000,

batch_size=16

)

print(f"\nFound {len(best_designs)} novel designs")

print(f"Best score achieved: {max(scores):.4f}")See the difference? The first approach optimizes within a predefined design space. The second explores the entire possibility of space, looking for solutions humans wouldn’t naturally consider.

The key insight: optimization assumes you know what good looks like. Reimagination discovers what good could be.

Real-World Examples of Reimagination

Autodesk demonstrated this with their generative design of a chassis component. Instead of asking “how do we make this part lighter,” they asked “what’s the optimal structure to handle these load cases?” The result: a design that reduced part count from eight pieces to one while cutting weight by 50%.

The design looks alien: organic, almost biological. That’s because it’s not constrained by assumptions about how parts should look or how they’ve traditionally been manufactured. It emerged purely from physical requirements.

Here’s what I mean by “alien”: imagine a car door frame that doesn’t look like a rectangle with rounded corners. Instead, it looks like tree branches — organic, flowing structures that follow stress lines. In one project I consulted on, this approach reduced the door frame weight by 35% while actually improving crash safety by 12% compared to traditional stamped steel designs. The engineers were skeptical until they ran the crash simulations.

The revealing part: when I show these designs to automotive engineers, the most common response is “customers would never accept that.” But they said the same thing about Tesla’s minimalist interiors five years ago. Now everyone’s copying them. They said it about BMW’s kidney grilles getting larger. They said it about touchscreens replacing physical buttons. Customer acceptance follows demonstration, not the other way around.

The Chassis Paradigm

For a hundred years, we’ve built cars around a fundamental principle: the chassis provides structural integrity, the body provides aesthetics and aerodynamics. This made perfect sense when you needed a rigid frame to mount a heavy engine and transmission.

But electric vehicles don’t have those constraints. The “engine” is distributed electric motors. The “fuel tank” is a flat battery pack that can serve as a structural element. Yet most EV manufacturers are still building separate chassis and bodies because that’s how we’ve always done it.

When you let generative AI design vehicle structure from scratch without assuming chassis/body separation it produces integrated designs where structure, aerodynamics, and interior space emerge from the same optimization process. These designs can be 30-40% lighter and 25% more aerodynamically efficient than traditional architectures.

I’ve seen these designs in confidential sessions with manufacturers. They’re weird. They challenge every assumption about what a car should look like. Some look more like aircraft fuselages than car bodies. Others have structural elements that flow from the roof to the floor in curves that seem random but are actually optimized for specific crash scenarios. And that’s exactly the point they’re not constrained by “this is how we’ve always done it.”

The Real Competition Isn’t Who You Think

The Tesla Lesson

Traditional automakers assumed their competition was other traditional automakers, all playing the same optimization game with slightly different strategies. Then Tesla showed up and changed the rules.

Tesla’s Giga casting process is a perfect example. They use AI-optimized designs to replace 70 separate stamped and welded parts with single aluminum castings. This wasn’t possible by asking “how do we optimize our stamping process?” It required asking “what if we rethought vehicle assembly entirely?”

The results speak for themselves: Tesla achieved profit margins of 16.3% in 2023, compared to traditional automakers averaging 5-7%. That’s not just better execution; it’s a different game.

Let me break down what this actually means in practice:

| Metric | Traditional OEMs | Tesla | Difference |

| Profit Margin | 5-7% | 16.3% | +132% |

| Parts per rear underbody | 70+ pieces | 1-2 castings | -97% |

| Assembly time | 2-3 hours | 10 minutes | -83% |

| Manufacturing CapEx per vehicle | $8,000-10,000 | $3,600 | -64% |

These aren’t incremental improvements. This is structural advantage.

The China Factor

Chinese manufacturers are moving even further. NIO’s battery-swapping stations, which replace a depleted battery in under three minutes, emerged from asking whether vehicle range should be solved through bigger batteries or different infrastructure. That’s a reimagination question, not an optimization question.

Think about what this actually means: instead of optimizing battery chemistry or charging speed the questions every Western manufacturer is asking, NIO asked “what if the battery doesn’t need to stay in the car?” This completely sidesteps range anxiety, eliminates the need for massive battery packs, and creates a subscription revenue model. It’s not a better answer to the old question; it’s a different question entirely.

BYD’s vertical integration — they manufacture everything from semiconductors to complete vehicles — allows them to use generative AI across the entire value chain rather than just optimizing individual components. When you control the full stack, you can ask more fundamental questions about how the pieces fit together.

I’m not saying Chinese manufacturers will necessarily win. But they’re asking different questions, and that’s dangerous for companies still optimizing within old paradigms.

The Pattern of Disruption

This is the same pattern we’ve seen in every major industry disruption:

Kodak had the first digital camera in 1975. They buried it because it would cannibalize film sales and their optimization mindset couldn’t accommodate reimagination. They kept optimizing film quality while digital cameras reimagined photography entirely.

Nokia dominated mobile phones by optimizing hardware and manufacturing. They had the best build quality, longest battery life, most durable phones. Then Apple asked whether phones should be optimized for calling or for computing. Nokia kept making better phones; Apple made a computer that could make calls.

Blockbuster optimized their retail experience: better store layouts, more inventory, faster checkout. Netflix asked whether video rental should happen in stores at all.

The technology wasn’t the disruption. The willingness to ask different questions was.

And here’s the uncomfortable truth: when I talk to automotive executives, most can recite these examples. They know the pattern. They just don’t believe it applies to them because “cars are different” or “we have physical constraints” or “our customers expect certain things.” That’s exactly what Kodak and Nokia said.

What Actually Needs to Change

Why “Be More Innovative” Doesn’t Work

The solution isn’t simply telling automakers to “be more innovative.” I’ve sat through enough strategy sessions to know that everyone wants to innovate. The problem is structural.

Public companies face quarterly earnings pressure. Ford has $43 billion invested in manufacturing facilities globally. You can’t just write that off to try something new. Dealer networks expect a steady supply of vehicles that look and function like vehicles. Supplier relationships are built around specific components and processes. Regulatory frameworks assume cars will have steering wheels, pedals, and mirrors.

These aren’t excuses, they’re real constraints that make reimagination genuinely difficult. But some changes are possible, even within these constraints.

Practical Steps Forward

1. Create genuinely independent innovation units

Not “innovation labs” that report to production engineering and get judged by production metrics. Separate entities with different success criteria, different timelines, and permission to challenge core assumptions. Give them real budgets and real autonomy.

Amazon does this with Lab126 (which created Kindle, Echo, Fire). Google did it with X (formerly Google X, which developed Waymo, Wing, Loon). These units can fail repeatedly because they’re not measured by quarterly production targets. That freedom to fail is what enables reimagination.

Here’s what this looks like structurally:

- Separate P&L: Not a cost center within production, but its own business unit

- Different metrics: Measured on learning and option value, not immediate ROI

- 3–5-year timelines: Not quarterly or annual goals

- Permission to cannibalize: Explicitly allowed to threaten existing products

- Different talent: Researchers and experimenters, not production engineers

2. Partner with generative AI researchers

Most automotive AI deployments focus on immediate production applications. That’s fine, but you also need teams exploring possibility spaces without immediate production constraints.

Partners with universities, AI research labs, or create internal research groups that aren’t tied to specific product timelines. Let them ask stupid questions like “what if cars didn’t have wheels?” Most explorations will lead nowhere. The few that lead somewhere will be transformative.

Specific actions:

- Fund PhD research at MIT, Stanford, CMU on automotive applications of generative AI.

- Create artist-in-residence programs bringing industrial designers to work with AI researchers.

- Sponsor competitions (like DARPA Grand Challenge) for radical vehicle concepts.

- Publish research openly attracts talent by being where interesting work happens.

3. Engage customers differently

Stop asking customers what they want within current paradigms. Of course they’ll say they want better range, faster charging, more comfortable seats. Those are optimization questions.

Instead, show them what’s possible. Tesla didn’t ask focus groups whether they wanted a 17-inch touchscreen replacing all physical controls. They built it, and customers discovered they loved it. Sometimes you need to show people the future rather than asking them to imagine it.

Better approach:

- Build concept vehicles that challenge assumptions

- Let customers experience radically different designs

- Measure reactions to actual prototypes, not descriptions

- Focus groups should react to prototypes, not imagine possibilities

4. Recognize what game you’re actually playing

The competition isn’t about who optimizes fastest. It’s about who’s willing to question what we’re optimizing for.

A McKinsey study found that 63% of automotive executives believe they’re “advanced” in AI adoption, primarily citing optimization use cases. Meanwhile, someone else is using the same technology to question whether we need steering wheels, whether vehicles should be owned or accessed, whether transportation should be optimized for individuals or communities.

Those are reimagination questions. And if you’re not asking them, someone else is.

Try This Yourself: A Practical Implementation

Want to experiment with these concepts? Here’s a practical starting point using publicly available tools and data.

Dataset and Methodology

The code examples in this article use synthetic data for demonstration purposes. For readers wanting to experiment with actual generative design:

Public datasets you can use:

Tools and frameworks:

- PyTorch or TensorFlow for neural network implementation

- Trimesh for 3D mesh processing in Python

- OpenFOAM for CFD simulation (open-source)

- FreeCAD with Python API for parametric design

Getting started:

# Install required packages

# pip install torch trimesh numpy matplotlib

import trimesh

import numpy as np

import torch

# Load a 3D model from Thingi10K or create a simple shape

def load_or_create_design():

"""

# Load a 3D model or create a simple parametric shape

"""

# Option 1: Load from file

# mesh = trimesh.load('path/to/model.stl')

# Option 2: Create a simple parametric shape

mesh = trimesh.creation.box(extents=[1.0, 0.5, 0.3])

return mesh# Convert mesh to voxel representation

def mesh_to_voxels(mesh, resolution=32):

"""

Convert 3D mesh to voxel grid for AI processing

"""

voxels = mesh.voxelized(pitch=mesh.extents.max()/resolution)

return voxels.matrix

# Visualize the design

def visualize_design(voxels):

"""

Simple visualization of voxel design

"""

import matplotlib.pyplot as plt

from mpl_toolkits.mplot3d import Axes3D

fig = plt.figure(figsize=(10, 10))

ax = fig.add_subplot(111, projection='3d')

# Plot filled voxels

filled = np.where(voxels > 0.5)

ax.scatter(filled[0], filled[1], filled[2], c='blue', marker='s', alpha=0.5)

ax.set_xlabel('X')

ax.set_ylabel('Y')About the Author

Nishant Arora is a Solutions Architect at Amazon Web Services specializing in Automotive and Manufacturing industries, where he helps companies implement AI and cloud technologies